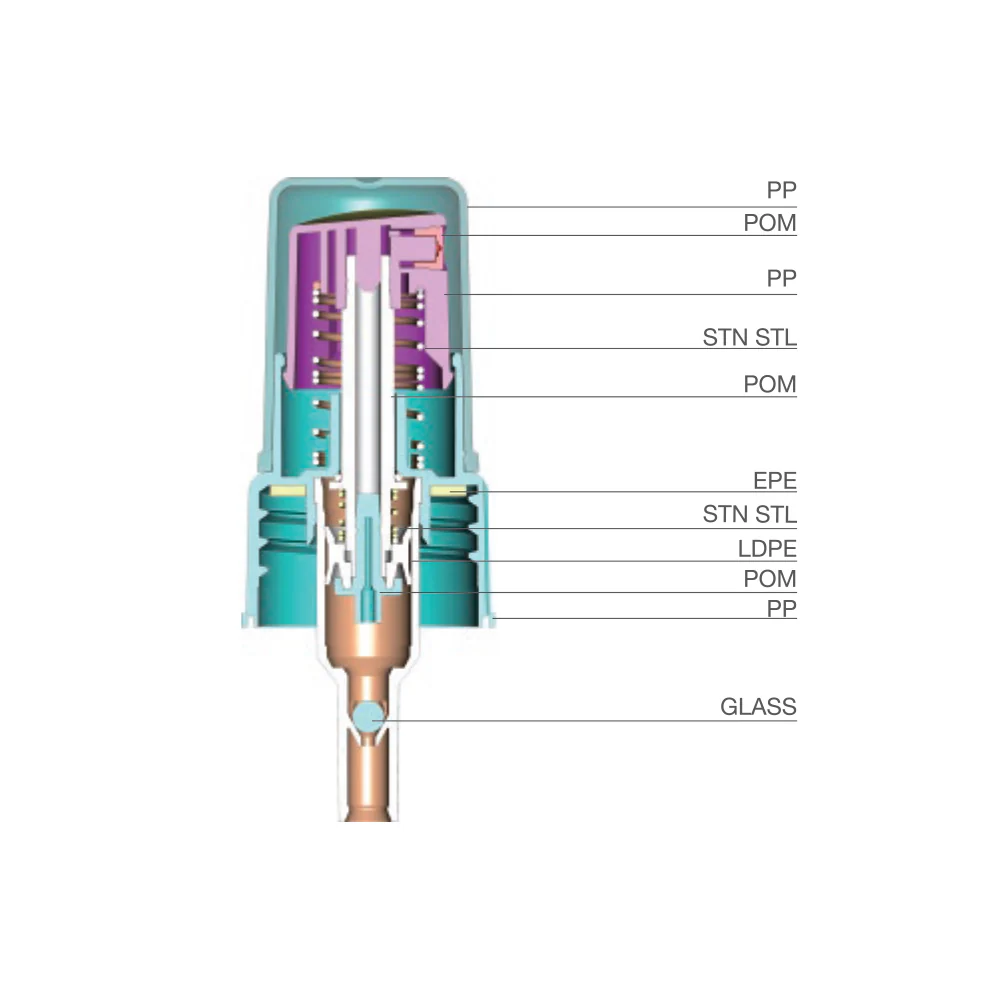

A mist spray pump uses a spring-loaded mechanism to create pressure, drawing liquid through a dip tube and forcing it through a nozzle that breaks it into a fine mist.

Priming: The pump draws liquid from the reservoir into its chamber.

Pressurization: The pump builds pressure within the system, forcing the liquid toward the nozzle.

Atomization:

As the pressurized liquid exits through the nozzle’s narrow orifice, it fractures into fine droplets due to shear forces and high velocity.

In air-assisted systems, additional airflow (via Venturi effect or compressed air) further breaks the liquid into mist.

Spray Release: The resulting mist is dispersed into the air, ideal for applications like humidification, gardening, or cosmetics.

What is the standard output per spray?

The typical output of a mist spray pump ranges from 0.1 ml to 0.3 ml per stroke, depending on the nozzle size and design.

Can mist sprayers be used for oil-based products?

Most mist sprayers work best with water-based or alcohol-based solutions. For oil-based products, you may need a specialized sprayer with a wider nozzle to prevent clogging.